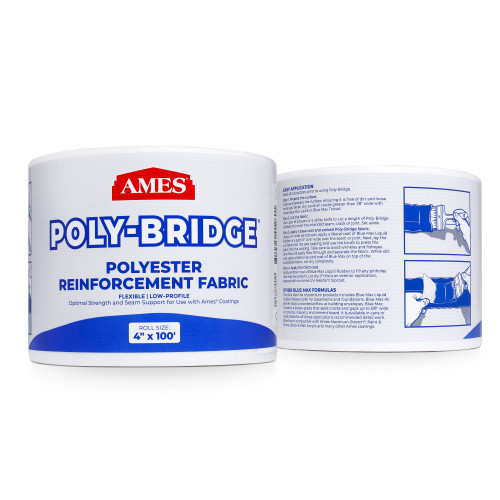

AMES® Poly-300 polyester reinforcement fabric helps seal and protect roofs & other surfaces from the elements. Poly-300 provides additional tensile strength and elongation to help resist tears and punctures as part of the AMES® Roof Coating System Membrane.

POLY-300™

Ames® Poly-300 polyester reinforcement fabric helps seal and protect roofs & other surfaces from the elements. Poly-300 provides additional tensile strength and elongation to help resist tears and punctures as part of the Ames® Roof Coating System Membrane.

Strong, conforming, & reinforcing to preserve the life of your roof

36"x100' roll of 100% polyester reinforcing fabric

To be used with Ames elastomeric coatings.

- SKU:

- ARF300

- UPC:

- 814580012625